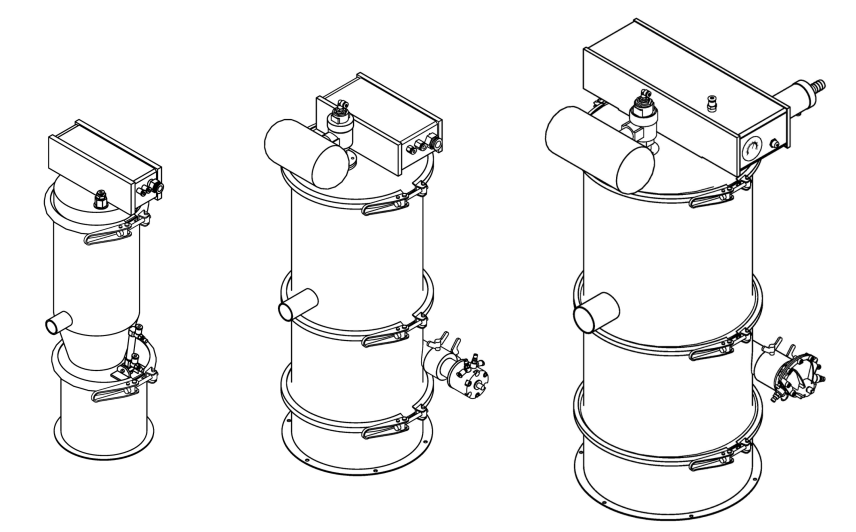

QVC Series Pneumatic Vacuum Conveyer

Ƙa'idar Aiki

Vacuum feeder injin ciyarwa ne ta hanyar amfani da famfo injin huhu azaman tushen vacuum.Tare da wannan injin ciyar da kayan za'a iya isar da shi kai tsaye daga akwati zuwa cikin mahaɗa, reactor, silo, injin kwamfutar hannu, injin tattarawa, sieve vibration, granulator, na'ura mai cike da capsule, rigar granulator, busassun granulator da disintegrator.Don amfani da wannan feeder na iya sauƙaƙa ƙarfin aikin ma'aikata, kawo ƙarshen gurɓataccen foda da tabbatar da cewa tsarin samarwa ya dace da bukatun GMP.

Lokacin da aka danna maɓallin “ON/KASHE”, iska mai matsewa ta shiga cikin injin famfo kuma ana rufe fitar da hopper, wanda ke motsa shi ta hanyar silinda mai huhu, ana kafa injin a hopper.Vacuum feeder zai samar da motsin iska a ƙarƙashin injin.Ana sarrafa ta wannan halin yanzu, ana ciyar da kayan zuwa injin hopper ta hanyar bututu.Bayan wani lokaci (lokacin ciyarwa, daidaitacce) iskar da aka datse ta yanke, injin famfo na pneumatic ba zai iya haifar da injin motsa jiki ba kuma fitar da hopper, wanda pneumatic Silinda ke tukawa, yana buɗewa, injin da ke cikin injin ciyarwa ya ɓace, kuma abu yana ta atomatik. fitarwa daga fitarwa zuwa na'urar karba (kamar latsa kwamfutar hannu da na'urar tattara kaya).A halin yanzu, matsewar iskan da aka adana a cikin tankin iska yana hura matatar a baya don yin tace ta atomatik.Bayan wani lokaci (lokacin fitarwa, daidaitacce) iskar da aka matse ta sake kunnawa, famfo famfo na pneumatic yana haifar da vacuum, an rufe fitarwa, vacuum feeder yana sake ciyar da kayan, ta wannan hanyar mai ciyarwa yana aiki a hawan keke don sanya kayan ciyar da kayan cikin karban injin ci gaba.

Don mai ciyar da injin ciyarwa tare da sarrafa matakin kayan abu ana samun ciyarwar atomatik tare da hopper na na'ura mai karɓar kayan ta hanyar sarrafa matakin kayan.Lokacin da matakin kayan ya fi matsayi a cikin hopper na na'ura mai karɓar kayan, mai ba da abinci ya daina ciyarwa, amma lokacin da matakin kayan ya yi ƙasa da matsayi a cikin hopper, mai ba da abinci zai fara ciyarwa ta atomatik.Kuma an kammala ciyar da na'ura mai karɓar kayan aiki ta haka.

Ƙayyadaddun Fasaha

| Samfura | Girman Ciyarwa (kg/h) | Amfanin iska (L/min) | Matsin Jirgin Sama (Mpa) |

| QVC-1 | 350 | 180 | 0.5-0.6 |

| QVC-2 | 700 | 360 | 0.5-0.6 |

| QVC-3 | 1500 | 720 | 0.5-0.6 |

| QVC-4 | 3000 | 1440 | 0.5-0.6 |

| QVC-5 | 6000 | 2880 | 0.5-0.6 |

| QVC-6 | 9000 | 4320 | 0.5-0.6 |

①Tsarin iska ya zama mara mai kuma babu ruwa.

②An ƙayyade ƙarfin ciyarwa tare da nisan ciyarwa na mita 3.

③Ayyukan ciyarwa sun bambanta da kayan aiki daban-daban.

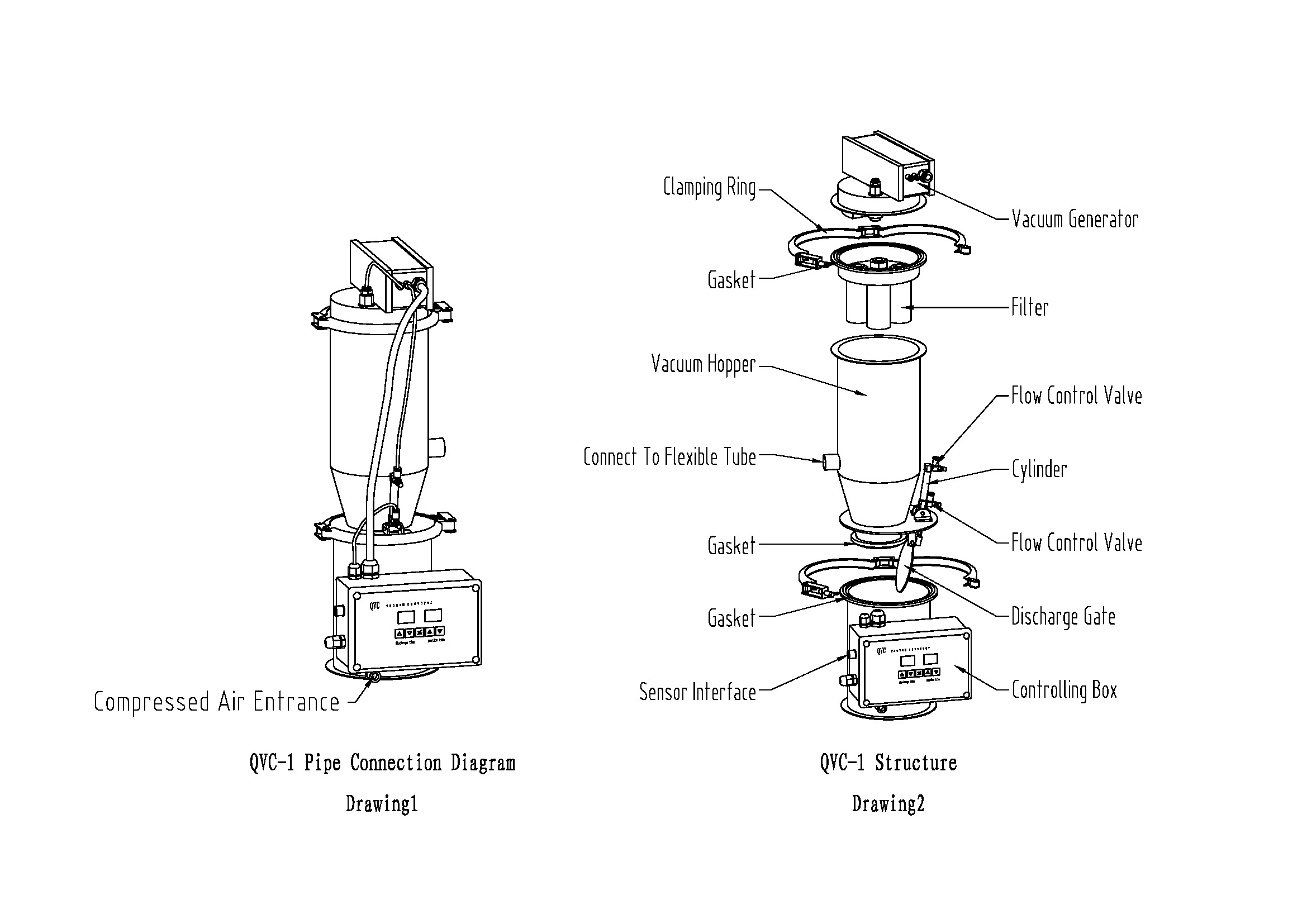

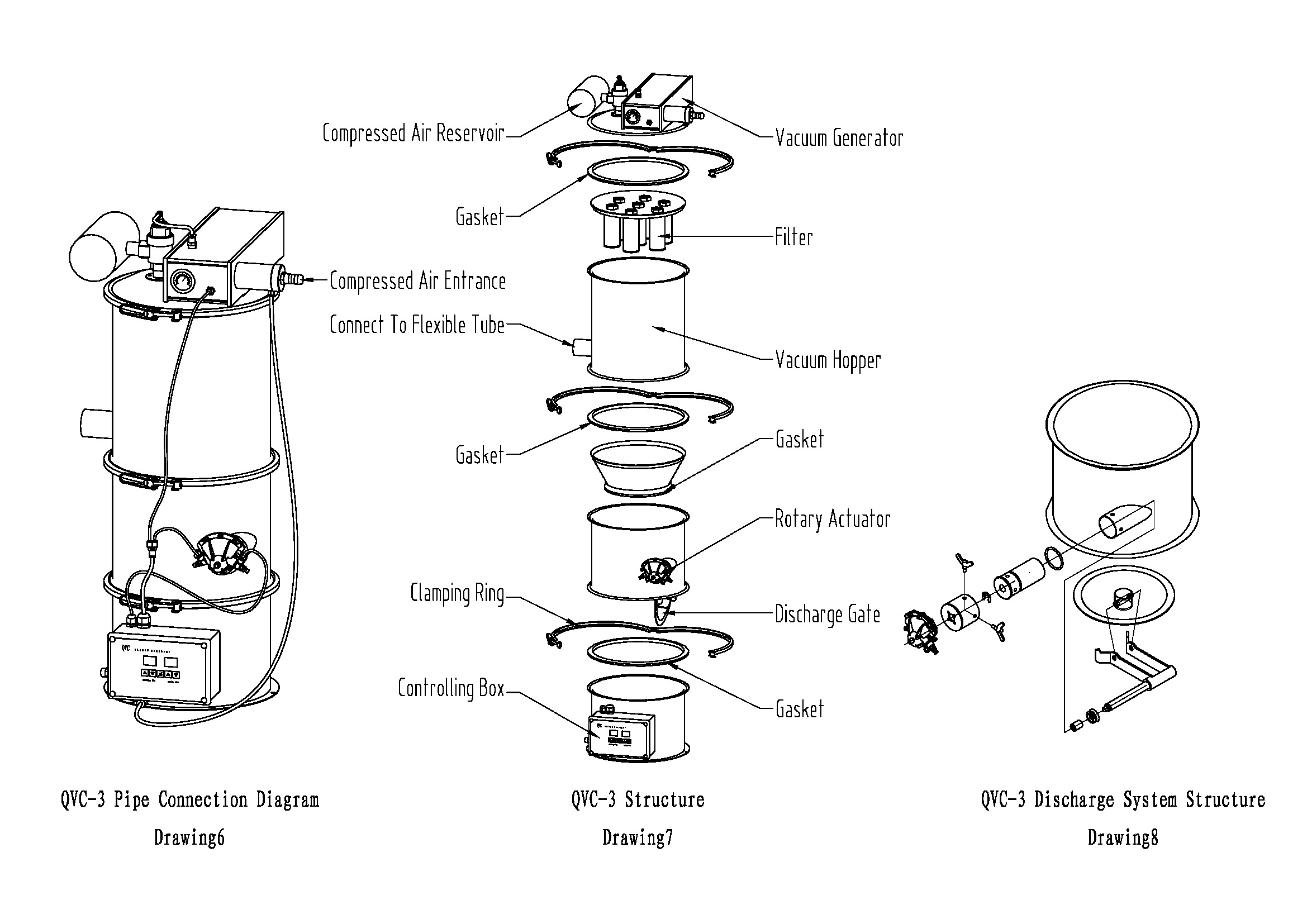

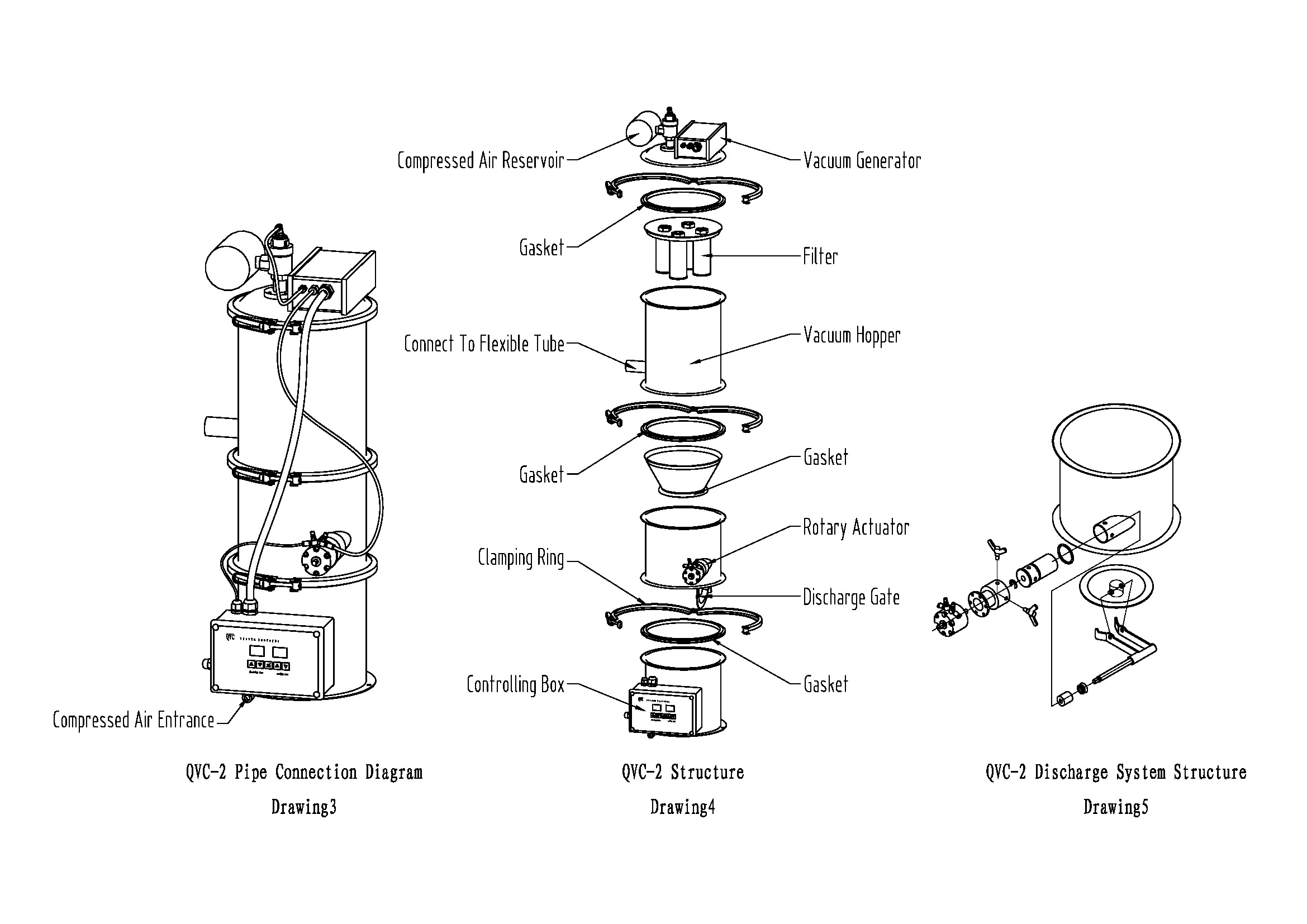

Gyarawa da Shigarwa

1.Gyar da injin hopper akan hopper na takarda takarda ko na'urar tattara kaya (ko wasu inji) tare da zobe.Idan ba za a iya saita injin hopper kai tsaye akan hopper na na'urar karban kayan ba za a iya yin tallafi don gyara injin hopper.

2. Akwatin sarrafawa yana rataye a kan vacuum hopper lokacin da aka kawo kaya, ana iya rataye shi a kan kowane wurare masu dacewa bisa ga yanayin aiki.

3.Connection na bututu don matsawa iska.

A. Zaɓin diamita na bututu don shigar da iska mai matsa lamba (yana nufin ɗakin shigarwa na inji):

Zaɓi 1/2 ″ bututu don QVC-1, 2, 3;

Zaɓi 3/4 ″ bututu don QVC-4, 5, 6;

Yi amfani da bututu φ10 PU kai tsaye don mai ciyar da injin QVC-1.

B. Ball bawul ko tace decompression bawul ya kamata a shigar a wurin da matsawa bututu iska shiga a cikin dakin na inji.

C. Don QVC-1, 2 masu ba da iska, haɗa madaidaicin bawul ɗin lalatawar tacewa zuwa haɗin shigar da iskar da aka matsa a ƙasan gefen akwatin sarrafawa.Girman bututun iska da aka matsa ya kamata ya zama daidai da haɗin shigar da iskar da aka matsa a ƙasan gefen akwatin sarrafawa.

D. Domin QVC-3, 4, 5, 6 masu ciyar da injin, haɗa fitar bawul ɗin tacewa kai tsaye zuwa haɗin shigar da injin janareta.Girman bututun da aka danne ya kamata ya zama daidai da haɗin shigar da iskar da aka matsa akan injin janareta.

E. Haɗa bututun iska da aka matsa tsakanin akwatin sarrafawa da injin janareta bisa ga zane na 1 da 3.

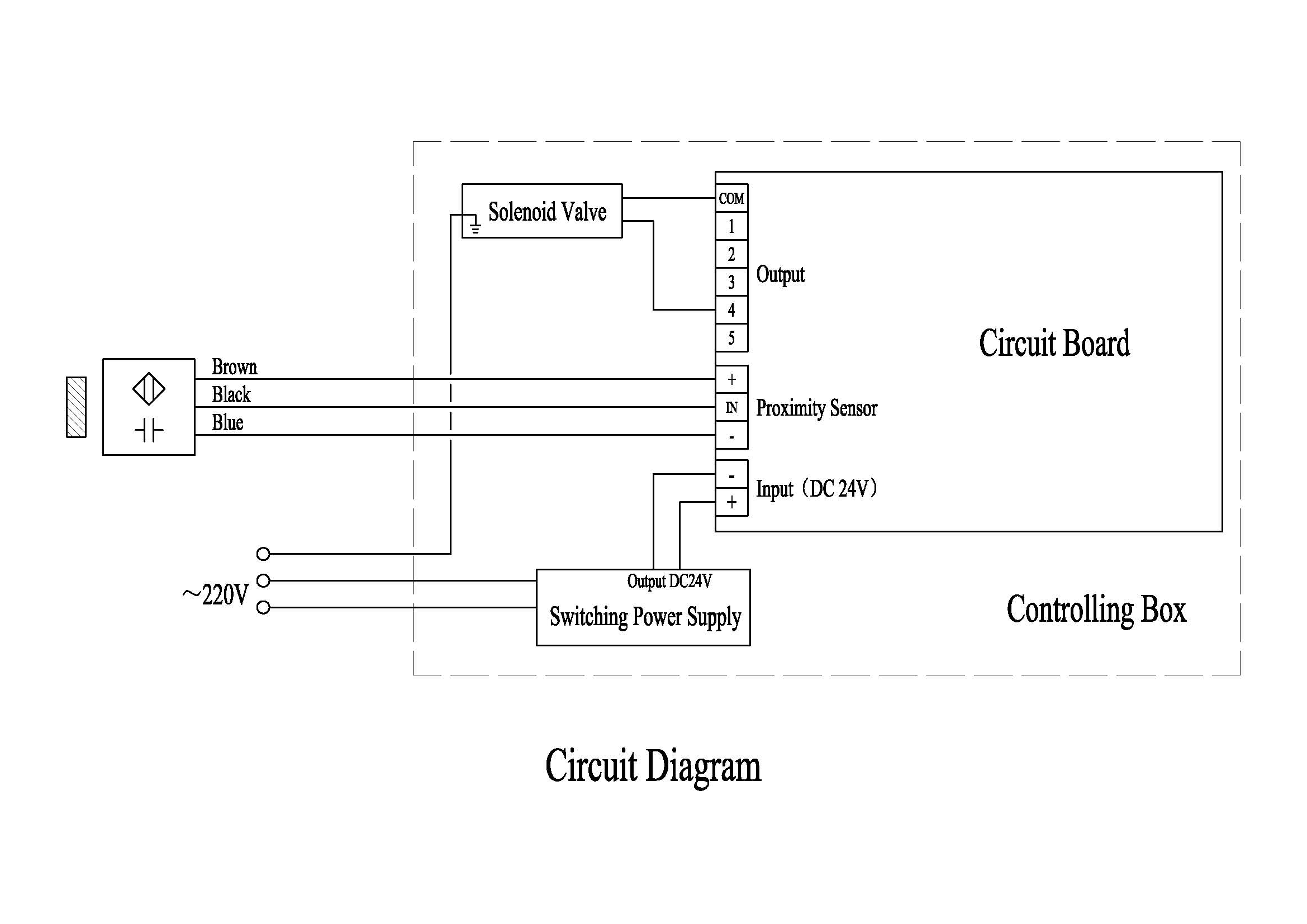

4.Plug AC 220V toshe zuwa soket na wutar lantarki, nunin lokaci akan akwatin sarrafawa yana kunne yanzu, wannan yana nufin an haɗa wutar lantarki akan tsarin.Kebul na bayanin kula dole ne ya zama layi uku.Ana buƙatar kafa majalisar sarrafawa don gujewa cewa guntun sarrafawa ya ƙare saboda tsangwama.Dubi tsarin lantarki don zanen waya don akwatin sarrafawa.

5.Maɓallin taɓawa don haɓaka lokaci / raguwa.Saita lokacin ciyarwa zuwa 5-15 seconds kuma saita lokacin fitarwa zuwa 6-12 seconds.Don kayan foda lokacin ciyarwa ya kamata a saita gajere kuma lokacin fitarwa yakamata a saita tsayi, yayin da kayan pellet lokacin ciyarwa yakamata ya zama tsayi kuma lokacin fitarwa yakamata ya zama guntu.

6.Latsa "ON / KASHE" key matsa iska ne ciyar da injin janareta, injin da aka samar a injin hopper da ciyar da aka gane.

7.A wannan lokacin ya kamata ku kula da matsa lamba na iska mai matsa lamba.Matsakaicin iskar da aka kawo yakamata ya zama 0.5-0.6Mpa.Matsin iskar da aka kawo yana nufin matsa lamba na iska mai matsa lamba a cikin tsarin lokacin da injin janareta yana aiki, watau lokacin ciyarwa.Akwai ma'auni a kan injin janareta don QVC-3, 4, 5, 6 kuma karatun akan ma'aunin ya kamata a ɗauke shi azaman ma'auni.Amma ga QVC-1, 2 babu ma'auni a kan injin janareta kuma ma'auni akan bawul ɗin lalatawar tacewa yakamata a ɗauke shi azaman misali.A cikin ɓangarorin ya kamata ku ba da kulawa ta musamman ga cewa matsi na iskar da aka kawo 0.5-0.6Mpa yana nufin yanayin iska a cikin tsarin yayin ciyarwa.Lokacin fitarwa ko kan jiran aiki matsa lamba da aka nuna akan ma'aunin akan bawul ɗin lalatawar tace yakamata ya zama 0.7-0.8Mpa.Yawancin masu amfani, lokacin da suka shigar da masu ciyarwa, galibi suna saita bawul ɗin lalatawar tacewa a 0.6Mpa.Idan a wannan lokacin injin janareta ya fara aiki da matsa lamba na tsarin ba zato ba tsammani ya faɗi zuwa 0.4Mpa, wanda ke haifar da gazawar ciyarwa ko gajeriyar ƙarfin ciyarwa.Don ciyar da nisa mai nisa ko mafi girman ƙarfin ciyarwa dole ne matsa lamba iska a cikin tsarin ya kai 0.6Mpa.

Matsalar Harbi

Ciyarwar da ta gaza ko gajeriyar ƙarfin ciyarwa yana faruwa akan mai ciyarwa duba mai ciyarwa kamar yadda ake bi:

1. Idan matsi na iskar da aka kawo ya kai 0.5-0.6Mpa.Matsin iskar da aka ba da ita yana nufin matsa lamba na iska a cikin tsarin lokacin da injin injin injin yana aiki.

2.Idan fitar da iska take.

A.Bayan yin aiki na dogon lokaci ana zuba wani foda mai kauri akan fitarwa, yana haifar da zubewar ruwa da zubar da ruwa.Sannan ya kamata a tsaftace fitar da ruwa.

B.Bayan aiki na dogon lokaci, gaskat ɗin da ke kan magudanar ya ƙare, wanda hakan ya haifar da zubewar ruwa da ɗigon ruwa.Sa'an nan ya kamata a maye gurbin gasket.

C.Bayan aiki na dogon lokaci wani abu yana faruwa ba daidai ba tare da tasiri da bugun jini na silinda pneumatic.Sa'an nan kuma ya kamata a maye gurbin silinda.

3.An katange tace.Busa tacewa tare da matse bututun iska a gaba da baya.Idan tace tayi sauri ba'a toshe shi.Idan kun ji an shaƙa tace, an toshe tacewa kuma yakamata a canza shi.Ko sanya matatar da aka katange a cikin mai tsabtace ultrasonic na tsawon mintuna 30 don tsaftacewa.

4.The abu tsotsa tiyo an katange da babban agglomerate abu.Wannan yawanci yana faruwa ne a mashigar bakin karfen kayan tsotsa bututun ƙarfe ko a mashigar injin hopper.

5.The clamping zobba ba a lazimta tsakanin famfo shugaban da hopper, tsakanin hopper sassan, sakamakon tsarin yayyo da haddasa kasa ciyarwa ko rage ciyar iya aiki.

6.Reverse busa tsarin tafi kuskure.Duk lokacin da mai ciyar da abinci ya fitar da abin da matsewar iska a cikin tankin iska yana hura matatar a baya don tabbatar da cewa akwai siririn foda a saman tace.Idan tsarin busawa na baya ya yi kuskure, ana ajiye foda mai kauri a saman tacewa, haɓaka juriya yana sa ciyarwa ba zai yiwu ba a kan injin ciyarwa.A wannan yanayin ya kamata a maye gurbin tsarin busa baya.

Tsaftacewa

A cikin kantin magani saboda nau'o'in nau'i daban-daban da lambobi masu yawa suna buƙatar tsaftacewa akai-akai.Mun yi cikakken la'akari da wannan buƙatun masu amfani lokacin da muka ƙirƙira injin ciyar da iska.Don tsaftacewa mai amfani kawai yana buƙatar yin abubuwa masu zuwa:

1.Sako da agraffes don cire pneumatic injin famfo taro.Pneumatic injin famfo, tankin iska da murfin an haɗa su azaman haɗaɗɗun taro, wanda baya buƙatar tsaftacewa da ruwa.

2.Cire taron tacewa da busa foda akan bututun tacewa tare da matsa lamba.Sannan a wanke shi akai-akai da ruwan zafi.Bayan wankewa sai a busa sauran ruwan da ke bangon bututun tacewa tare da matse iska.Yanzu ya kamata bututun tacewa ya zama mai sauri sosai bayan busawa akai-akai.Idan ka ji tace an shake, wannan yana nufin akwai sauran sauran ruwa a bangon bututun tacewa.Kuma kuna buƙatar ci gaba da hura shi da matsewar iska, sannan a bar shi ya huce ko ya bushe.

3.Sake zoben matsewa, cire hopper ɗin kuma a wanke hopper da ruwa.